Vertical Leaf Filter Bags for Chemical Industries

- Low operating cost with simple structure and easy maintenance

- Wide industrial applicability with reliable solid-liquid separation performance

- Star-arranged filter elements ensure high efficiency and stable filtration

- High-quality leaf filter bags improve durability and filtration accuracy

General introduction:

The vertical leaf filter as a type of solid-liquid separation equipment with the properties of low cost, wide applicability, simple operation, and low labor intensity for workers, which is widely used in chemical industries.

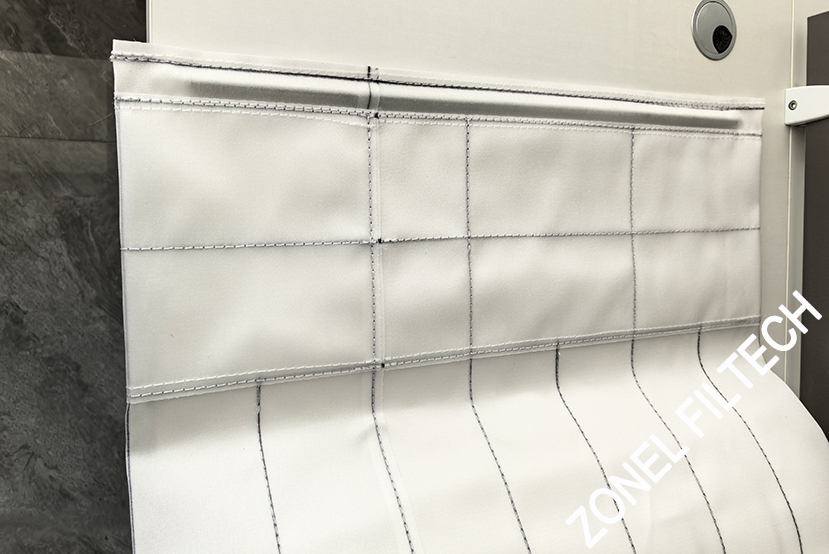

The vertical leaf filter mainly consists of the filter vessel, filter elements (filter leaves and filter leaf bag), a high-level tank, and a pressure relief tank. The filter elements are arranged in a star shape, with each element containing a filter plate and a filter bag, which can be treated as the heart of the filter system.

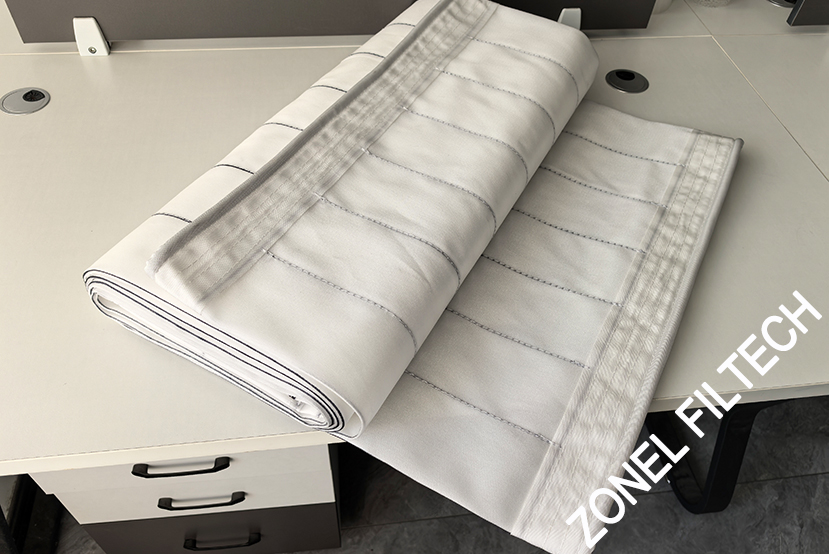

Zonel Filtech mainly develops and produces high-quality leaf filter bags for various industrial applications.

Working principle:

During the filtration process, the crude liquid is conveyed into the filter vessel.

Under a certain pressure, the filtrate passes through the filter bags of the leaf filter then flows into the filtrate collection tank through a conduit; the filter cake forms on the outside of the leaf filter cloth or filter bags.

After a certain period of filtration, the pressure inside the filter vessel is reduced to atmospheric pressure, and the liquid in the high-level tank back flushes the vertical leaf filter sleeve to drop the filter cake and complete the sludge discharge process.

So one working cycle of this equipment consists of 3 parts: feeding, cake formation, and sludge discharge from the filter leaf bag.

The properties of the vertical leaf filter bag from Zonel Filtech:

- Adopted the industrial grade monofilament and multi-filament, chemical resistance, and low shrinkage;

- Customized according to different applications, with different pore sizes available.

- High flow rate, enlarges the output efficiently;

- Optimized weaving pattern, high filter efficiency, lower clog rate, durable;

- Smooth surface design, easy cake release, easy to rewash/regenerate.

Applications

From abundant experiences are shown that the vertical leaf filter is the best suited to the requirements of alumina production, which are widely used in alumina production operations. Currently, the leaf filter material / alumina plant filter cloth from Zonel Filtech are widely used in alumina production (filter bag for alumina production), include the production procedures of:

- Red Mud Slurry Filter with red mud filter bag: Processing the red mud slurry after the Bayer process, the leaf filter clothcan help to reduce the water content of the red mud to meet the requirements for storage or comprehensive utilization;

- Refined liquidFiltration: Final purification of the sodium aluminate liquor, removing suspended particles so as to ensure the purity of electrolytic aluminum (sodium aluminate solution filter);

- Seed Filtration: Separating aluminum hydroxide seeds in the sintering process(aluminum hydroxide seeds filter), etc.

The leaf filter bags from Zonel Filtech also adopted to industries of sugar refining, vanadium extraction from steel slag, etc.

Any filter materials needed for leaf filters, welcome to contact Zonel Filtech!