With increased demand for higher filtration efficiency, operational cost savings, and sustainability, businesses must make informed choices between different filtration technologies. Among the most widely used are high flow pleated filter cartridges and traditional depth filters. While both serve to remove particles from fluids, they operate on distinct principles and offer different advantages depending on application requirements.

This article provides an in-depth comparison of high flow pleated filter cartridges and traditional depth filters, covering their design, filtration mechanism, efficiency, lifespan, maintenance needs, cost implications, and application suitability.

Table of Contents

ToggleWhat Are High Flow Pleated Filter Cartridges?

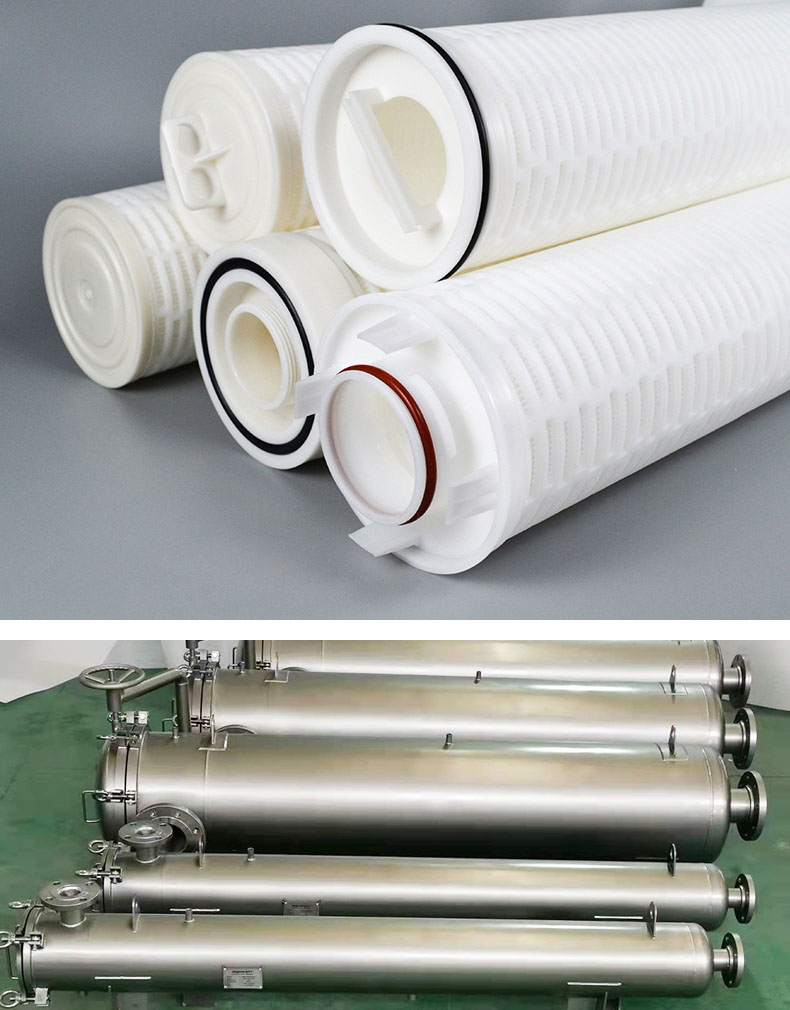

High flow pleated filter cartridges are advanced filtration elements that use a pleated design to maximize surface area. Available in various micron levels, these polyester or polypropylene filters use pleated media layers to let fluids pass while effectively capturing particles with minimal flow restriction for efficient filtration performance.

Key characteristics include:

- High surface area per cartridge

- High flow rate capabilities (often up to 500 GPM per cartridge)

- Long service life

- Compatibility with large-volume industrial processes

- Available in both absolute and nominal micron ratings

What Are Traditional Depth Filters?

Traditional depth filters are composed of thick media, often made from polypropylene, cellulose, or glass fiber. They work by allowing fluids to pass through a dense, three-dimensional matrix that captures particles throughout the depth of the media, not just on the surface.

Key characteristics include:

- Graded-density structure

- Excellent dirt-holding capacity

- Cost-effective for low-flow applications

- Nominal micron ratings (less precision than absolute-rated filters)

Filtration Mechanism: Surface vs. Depth

The way these two kinds of filters capture particles is where they diverge most:

Pleated filters primarily perform surface filtration. Particles are captured on the outer layers of the pleated media. Because of their pleated structure, they offer a large surface area for filtration, resulting in lower pressure drops and higher flow rates.

Depth filters perform depth filtration, where particles are captured throughout the entire thickness of the media. This allows for effective removal of a wide range of particle sizes, especially deformable or gel-like contaminants.

Comparative Summary

| Feature | High Flow Pleated Filters | Traditional Depth Filters |

| Filtration type | Surface | Depth |

| Particle retention | Surface layer | Entire media volume |

| Media structure | Pleated, multi-layer | Thick, dense matrix |

| Dirt-holding capacity | Moderate to high | High |

Filtration Efficiency

High Flow Pleated Filters

High flow filters are often available in absolute-rated media, which means they can guarantee removal of particles at the specified micron rating. For example, a 5-micron absolute pleated cartridge will retain 99.98% of all particles ≥5 microns in size. This makes them highly reliable for critical applications, such as pre-RO filtration, oil removal, or final polishing.

Traditional Depth Filters

Depth filters are usually nominal-rated, meaning they can remove a stated percentage (often 85%) of particles at a given size. While they may not provide the same precision as absolute filters, their layered structure can effectively handle particle size variations, agglomerates, and viscous fluids.

Flow Rate and Pressure Drop

One of the most compelling advantages of high flow pleated cartridges is their high flow rate capability with lower differential pressure. This means fewer cartridges are needed for the same throughput, reducing housing size, operational complexity, and maintenance frequency.

In contrast, depth filters usually have higher pressure drops and lower flow rates, requiring more cartridges or housings to handle the same process volume.

Example:

- A single high flow pleated filter cartridge (60” long) can handle up to 500 GPM.

- A standard depth filter cartridge (10” long) handles around 3-5 GPM.

Comparative Table:

| Parameter | High Flow Pleated Cartridges | Traditional Depth Filters |

| Flow Rate | High (up to 500 GPM) | Low to moderate |

| Initial Pressure Drop | Low | Higher |

| Housing Size | Compact | Larger |

Lifespan and Maintenance

High Flow Filters

Due to their large surface area and low pressure drop, high flow filters often enjoy a longer service life, reducing changeout frequency and downtime. Moreover, they are easier to clean and replace due to their user-friendly design.

Depth Filters

While depth filters offer high dirt-holding capacity, they can clog more quickly when subjected to high solids loads or inconsistent feedwater quality. They are also less tolerant to pressure spikes and may collapse under certain operating conditions.

Cost Considerations

At face value, depth filters are cheaper per unit than high flow pleated cartridges. However, when considering total cost of ownership (TCO)—which includes labor, downtime, filter housing, and disposal—high flow pleated cartridges often come out ahead in large-scale applications.

Total Cost Comparison Factors:

- Filter housing size: Larger for depth filters

- Changeout frequency: Higher for depth filters

- Labor and maintenance: Higher for depth filters

- Disposal cost: More frequent with depth filters

Application Suitability

High Flow Pleated Filter Cartridge Applications

Ideal for:

- Power plant water intake filtration

- Reverse osmosis (RO) pre-filtration

- Oil and gas processing

- Food and beverage clarification

- Industrial cooling water filtration

Their ability to handle large flow rates, coupled with precise micron retention and compact design, makes them perfect for high-volume, critical operations.

Traditional Depth Filter Applications

Best suited for:

- Pharmaceutical and cosmetic products

- Chemical processing with viscous fluids

- General-purpose water filtration

- Prefiltration in food and beverage

Depth filters are often selected for batch operations or systems where cost control and particle diversity matter more than flow rate or micron precision.

Environmental Impact and Sustainability

High flow pleated cartridges support sustainability by:

- Reducing material waste (fewer cartridges used)

- Minimizing energy use due to lower pressure drop

- Lowering transport and storage costs due to compact size

Depth filters, while recyclable in some forms, typically generate more waste due to frequent changeouts and larger filter volumes.

Regulatory and Quality Considerations

Many high flow pleated filters meet stringent FDA, NSF, and USP Class VI standards, making them appropriate for sensitive industries like pharmaceuticals and food processing. Manufacturers also provide extensive validation data.

Depth filters are also available with certifications but may vary more in consistency due to material composition and production methods.

Choosing the right filtration system is about balancing efficiency, cost, longevity, and suitability for your operation. High flow pleated filter cartridges offer high throughput, precision filtration, and long-term savings in industrial settings with large fluid volumes. Meanwhile, traditional depth filters continue to hold their place in cost-sensitive or small-batch operations, especially where wide-ranging particle sizes and flexible handling are required.

As industries move toward higher productivity and sustainability, the preference is increasingly shifting toward high flow solutions. However, the final choice must always align with your process needs, operating conditions, and regulatory obligations. Collaborating with experienced filter suppliers can help ensure that you select the most effective and economical filtration solution for your application.