In any filtration process, the micron rating plays a decisive role in determining how effectively particles are removed from liquids or gases. Whether you’re filtering water, chemicals, food products, or paint, selecting the correct micron rating can dramatically impact system efficiency, product quality, and maintenance costs.

Choosing the wrong filter can lead to premature clogging, contamination, or unnecessary energy consumption. Understanding what the micron rating represents—and how it relates to your application—is essential for making the right decision.

Table of Contents

ToggleUnderstanding Micron Rating

A micron (μm) equals one-millionth of a meter, representing the particle size a filter can effectively capture or remove.

For instance:

- Human hair: approximately 70 μm

- Fine sand: around 100 μm

- Red blood cell: about 8 μm

- Bacteria: roughly 1 μm

- Smoke particles: less than 0.5 μm

Micron ratings generally fall into two categories:

- Nominal micron rating: Indicates the filter removes roughly 80–90% of particles at the rated size.

- Absolute micron rating: means the filter removes 99.9% or more of particles equal to or larger than the rated size.

This distinction is crucial. A 10 μm nominal filter may allow many fine particles through, whereas a 10 μm absolute filter provides near-total capture.

The Role of Micron Rating in Filtration Performance

Micron rating doesn’t just define what particles a filter can trap—it directly affects flow rate, pressure drop, and filter service life.

- Smaller micron ratings (fine filtration): Provide cleaner output but reduce flow rate and increase clogging risk.

- Larger micron ratings (coarse filtration): Allow higher flow rates but permit more contaminants to pass through.

Additionally, the filter media type (felt, mesh, or membrane) impacts accuracy. For example:

- Needle felt filters function as depth filters, capturing and retaining particles deep within interlaced fiber layers.

- Monofilament mesh filters are surface filters—particles are trapped on the surface.

Achieving efficient system operation requires balancing micron size selection with optimal flow rate and filter lifespan.

Relationship Between Micron Rating and Performance

| Micron Rating (μm) | Filtration Type | Flow Rate | Pressure Drop | Typical Usage |

| 800–200 | Coarse | Very High | Low | Paints, resins, sand removal |

| 100–50 | Medium | High | Moderate | General process filtration |

| 25–10 | Fine | Medium | Moderate-High | Beverage, oil, chemical |

| 5–1 | Very Fine | Low | High | Sterile, pharmaceutical |

| 0.5–0.1 | Ultra-Fine | Very Low | Very High | Semiconductor, lab-grade |

Factors to Consider When Choosing a Micron Rating

Selecting the right micron rating requires evaluating several process variables that influence filtration efficiency and performance.

Type and Size of Contaminants

Start by identifying what you’re filtering out. If your fluid contains visible particles (sand, debris), a coarse filter around 100 μm might suffice. For invisible bacteria or colloids, you’ll need sub-micron filtration.

Required Filtration Efficiency

- Applications differ in required purity:

- Pre-filtration: 50–100 μm filters remove large debris before fine filters.

- Final filtration: 0.2–5 μm filters ensure high purity or sterility.

Fluid Properties

Viscosity and temperature affect how fluids flow through a filter. High-viscosity oils may require larger micron filters to avoid excessive pressure drop.

Flow Rate and System Pressure

Selecting a too-fine filter can drastically reduce flow and strain pumps. Always balance filtration precision with process efficiency.

Filter Media Compatibility

- Different filter materials perform best in particular operating environments.

- Polypropylene (PP): resistant to acids and alkalis.

- Nylon: excellent abrasion resistance.

- PTFE: superior for aggressive chemicals or high temperatures.

- Polyester (PET): general-purpose and economical.

Common Micron Ratings and Their Applications

Different industries require varying degrees of filtration precision. The table below summarizes typical micron ranges used in common processes.

Micron Rating vs. Application Example

| Micron Rating (μm) | Application | Industry |

| 800–400 | Resin, paint pre-filtration | Coatings, Automotive |

| 200–100 | Sand, rust, coarse sediment | Water Treatment |

| 50–25 | Process liquids, chemical slurries | Petrochemical |

| 25–10 | Clarification of beverages | Food & Beverage |

| 5–1 | Bacteria removal, polishing filtration | Pharmaceutical |

| 0.5–0.1 | Ultra-pure liquids, semiconductor use | Electronics, Lab |

This table illustrates that a 25 μm filter might be sufficient for juice production, but pharmaceutical-grade water needs filtration down to 0.2 μm.

How to Test and Verify Micron Effectiveness

Choosing a micron rating doesn’t end with selection—it requires verification to ensure expected performance.

Particle Size Analysis

Techniques like laser diffraction or microscopic examination determine the size distribution of contaminants in your system. This helps match filter ratings accurately.

Filter Efficiency Testing

- Beta Ratio (β): Indicates how efficiently a filter captures particles of specific size.

- Example: β = 200 means 199 out of 200 particles are captured (99.5% efficiency).

- Retention Efficiency: Determines the fraction of particles retained after multiple passes.

Supplier Certifications

- Always source filters from suppliers adhering to standards like:

- ISO 9001 (quality management)

- FDA-compliant materials

- NSF/ANSI 61 certification for safe drinking water systems

- Certified filters ensure consistent micron accuracy and safe operation.

Matching Micron Rating to Filter Type

Different filter types serve distinct process requirements:

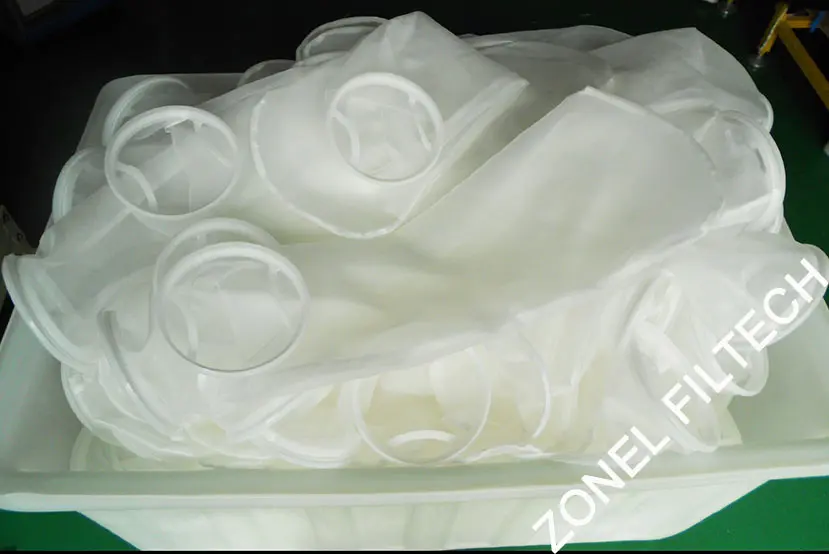

Filter Bags

- Offer high flow rates and large dirt-holding capacity.

- Typical ratings: 1–800 μm.

- Commonly used in industrial, food, and chemical processes.

Filter Cartridges

- Provide high precision and better consistency for fine filtration.

- Typical ratings: 0.2–50 μm.

- Ideal for pharmaceutical and beverage filtration.

Filter Cloths & Membranes

- Used in press filters or specialized equipment.

- Allow customized pore sizes and high chemical compatibility.

Example Compatibility Overview

| Filter Type | Micron Range (μm) | Best For |

| Filter Bag | 1–800 | Liquids with suspended solids |

| Cartridge | 0.2–50 | Precision filtration |

| Cloth/Membrane | 0.1–200 | Solid-liquid separation |

Selecting both the correct filter type and micron rating ensures maximum process reliability.

Common Mistakes When Selecting Micron Ratings

Over-Filtration (Too Fine)

Choosing a smaller micron rating than necessary increases pressure loss, accelerates clogging, and shortens filter life. This leads to frequent replacement and higher operational costs.

Under-Filtration (Too Coarse)

A coarse filter may fail to remove fine contaminants, causing product quality issues or equipment damage downstream.

Ignoring Particle Distribution

Not analyzing contaminant size distribution can result in mismatched filters. It’s crucial to test actual process fluids before finalizing a micron rating.

Neglecting Maintenance Impact

If the filter is hard to clean or replace, the operational cost may outweigh the filtration benefit, even if the micron rating seems ideal.

Case Study: Practical Micron Rating Selection

Case 1: Beverage Production

A juice bottling company used 10 μm nominal filters for final clarification. The resulting product had a slight haze, causing rejection in quality tests.

After switching to a 5 μm absolute-rated filter, the juice clarity improved, customer complaints dropped by 30%, and filtration consistency stabilized.

Case 2: Paint Manufacturing

A paint manufacturer filtering resin and pigments used 50 μm bags but faced frequent nozzle blockages in their spray systems.

By shifting to a 25 μm felt bag filter, they reduced clogging incidents by 40% while maintaining flow efficiency.

These cases highlight the value of trial-based selection—testing multiple micron ratings before full-scale adoption ensures optimal performance.

Selecting the right micron rating is both a science and an art. It depends on understanding your fluid characteristics, contamination level, and process goals. The best choice balances filtration accuracy, system performance, and maintenance cost.

To summarize:

- Know your contaminants: Identify the size and type of particles.

- Define your filtration goal: Pre-filtering or final polishing.

- Test and validate: Use Beta ratio and particle analysis for accuracy.

- Consult experts: Reliable filter suppliers can recommend ideal ratings for your operation.

An optimized micron rating doesn’t just filter better—it enhances product quality, minimizes downtime, and improves overall operational efficiency.