Among the different types of pressure filtration systems, vertical leaf filters are particularly effective for batch processing in industries like chemicals, pharmaceuticals, food processing, and wastewater treatment. One of the key components that make vertical leaf filters work efficiently are the filter bags. These specialized filtration elements serve a critical role in the filtration process, ensuring that the separation of solids from liquids occurs effectively and continuously.

Table of Contents

ToggleWhat is a Vertical Leaf Filter?

A vertical leaf filter is a type of pressure filter that utilizes a set of vertically mounted filter elements—referred to as “leaves”—to separate solids from liquids. The leaves have filter bags that trap solids and allow liquid passage. The liquid is pumped into the filter vessel under pressure, and as the liquid moves through the filter bags, solids accumulate on the filter media.

The filter leaves are arranged inside the filter vessel in such a way that they maximize surface area for filtration. The process is highly efficient and can be automated for continuous operation, which is why it is widely used in various industries where high-efficiency filtration is essential.

Pressure Filtration Explained

Pressure filtration is a method that forces a liquid through a filter medium under pressure. This process is significantly different from gravity filtration, where the liquid flows through the filter due to its own weight. Pressure accelerates filtration, enabling both continuous and batch processing.

In pressure filtration systems, the application of pressure enhances the filtration rate, allowing the system to handle larger volumes and thicker slurries. Over time, the solid particles accumulate, forming a filter cake. This cake acts as an additional filtering layer, improving the filtration process.

Types of Pressure Filtration Systems:

- Plate and frame filters: Common in batch processes, suitable for handling large volumes.

- Rotary drum filters: Ideal for continuous operation.

- Vertical leaf filters: Excellent for batch filtration, especially when large surface areas and high efficiency are needed.

Working Principles of Vertical Leaf Filters

Basic Filtration Process

The vertical leaf filter operates through a combination of gravity and pressure. Step-by-step explanation of the working principle:

- Loading the Filter: The slurry or liquid mixture containing solids is pumped into the filter chamber under pressure.

- Filtration Cycle: As the slurry enters the vessel, the filter bags on each leaf capture the solid particles while the liquid passes through.

- Cake Formation: The solids gather on the filter bags’ surface, creating a filter cake. The cake thickens over time as more solids are captured.

- Cake Compression and Discharge: Once the filter cake has built up to a certain level, the filtration process is stopped, and the cake is removed from the filter bags. This can be performed manually or automatically.

- Cleaning Cycle: After the filtration cycle, the filter bags may undergo cleaning through backwashing or vibration to remove any remaining solids, preparing them for the next cycle.

Pressure Application in Vertical Leaf Filters

Pressure plays a crucial role in the functioning of vertical leaf filters. It forces the liquid through the filter bags, causing the solid particles to be trapped on the surface. The pressure not only increases the flow rate but also allows the system to filter thicker slurries, which would be difficult to filter using gravity alone.

In vertical leaf filters, the liquid is forced vertically through the filter bags. This design allows the filter bags to have a high surface area, improving filtration efficiency. The system also allows for better control of the pressure, which can be adjusted depending on the type of material being filtered.

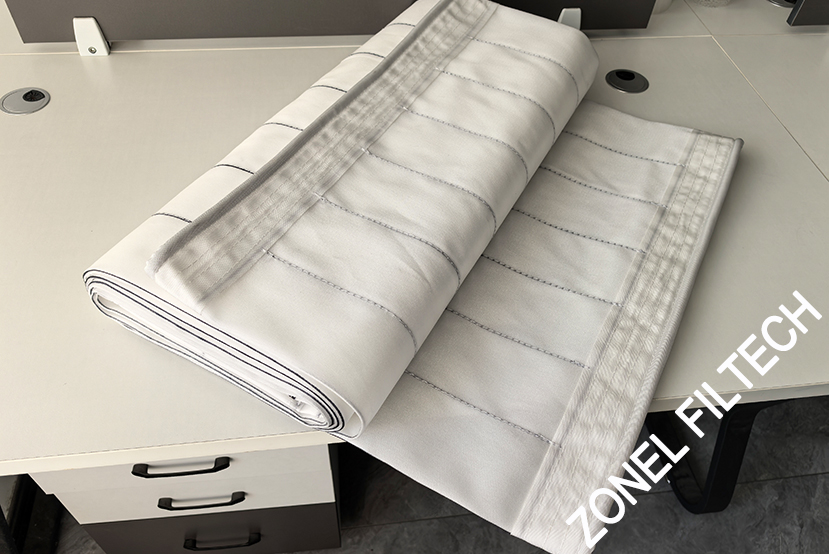

Types of Vertical Leaf Filter Bags

The filter bag in a vertical leaf filter is an essential component that directly impacts filtration performance. Different types of filter bags are used based on the filtration requirements, including the following:

Woven Filter Bags

Woven filter bags, typically made of polyester or polypropylene, offer excellent strength and durability for filtration.They are suitable for medium to high viscosity liquids and are often used in industries like chemicals and food processing.

Advantages:

- High strength and durability

- Easy to clean and reuse

- Versatile for various applications

Disadvantages:

- Less effective at filtering very fine particles

Non-Woven Filter Bags

These bags offer better filtration for fine particles, as they have a denser structure compared to woven bags.

Advantages:

- Superior filtration of fine particles

- Suitable for fine solids and high-quality filtration

- Better for use with low viscosity liquids

Disadvantages:

- More expensive than woven bags

- Less durable in high-pressure applications

Mesh Filter Bags

Mesh filter bags are made from a mesh material, typically stainless steel or nylon, which makes them highly resistant to wear and tear. These bags excel in coarse filtration and are suitable for high-temperature use.

Advantages:

- Excellent for coarse filtration

- High resistance to temperature and pressure

- Long service life

Disadvantages:

- Less effective for fine filtration

- Can be more expensive than other types

Comparison of Filter Bag Types

| Filter Bag Type | Material | Advantages | Disadvantages | Best For |

| Woven | Polyester/Polypropylene | Durable, easy to clean | Less effective for fine particles | Medium to high viscosity |

| Non-Woven | Synthetic fibers | Superior fine filtration | Higher cost | Fine solids and liquids |

| Mesh | Stainless steel/Nylon | High temperature resistance | Less effective for fine filtration | Coarse filtration |

Factors Affecting Filter Bag Performance

The performance of filter bags in vertical leaf filters depends on several factors, including:

Material Selection

The material used for the filter bags affects filtration efficiency, durability, and the types of liquids it can process. For example, polypropylene bags are suitable for acid filtration, while polyester bags are more common for general filtration.

Pore Size and Permeability

Filter bags come in a range of pore sizes. A smaller pore size results in finer filtration but can lead to clogging if not properly managed. The permeability of the bag material also affects the filtration rate.

Pressure and Temperature

Consider the filter bags’ maximum pressure and temperature to prevent damage. Bags designed for higher pressures are typically made of more robust materials.

Cake Formation

As the filter cake accumulates, more pressure is needed to pass the liquid. Over time, the filter bag may experience increased resistance, leading to slower filtration rates and the need for maintenance or cleaning.

Maintenance and Care of Vertical Leaf Filter Bags

Routine cleaning, inspections, and timely replacements are vital to keep filter bags efficient and extend their service life. Below are some key maintenance tips:

Cleaning Methods

Various cleaning methods for vertical leaf filter bags include:

- Backwashing: Reversing the flow of liquid through the bag to remove accumulated solids.

- Vibration: Applying vibration to dislodge solids from the bag surface.

- Washing: Manual washing or automated cleaning systems that use water or chemical agents to clean the bags.

Inspection and Replacement

Regularly check filter bags for wear, damage, or signs of deterioration. If the bag material is torn or the bag has become too clogged to clean, it should be replaced.

Best Practices

- Monitor the pressure differential between clean and dirty sides of the filter to detect when cleaning is needed.

- Keep track of filtration cycles to avoid overloading the filter bags.

Maintenance Methods for Vertical Leaf Filters

| Maintenance Method | Description | Best For |

| Backwashing | Reversing flow to remove solids | Prevent clogging and improve flow |

| Vibration | Applying vibration to dislodge solids | Cleaning without chemicals |

| Washing | Using water or chemicals to clean bags | Heavy cleaning and reusability |

Applications of Vertical Leaf Filter Bags

Vertical leaf filters are employed in various industries for efficient filtration. Below are some common applications:

Chemical Industry

In the chemical industry, vertical leaf filters remove solids from slurries, requiring bags resistant to chemicals and high temperatures.

Food Processing

Vertical leaf filters are used for filtering edible oils, fruit juices, and other liquids in the food industry. The bags must be food-grade and able to handle high-viscosity liquids.

Pharmaceuticals

Pharmaceutical manufacturers use vertical leaf filters to purify active ingredients. The filter bags must meet stringent cleanliness standards to avoid contamination.

Wastewater Treatment

In wastewater treatment plants, vertical leaf filters are used to remove suspended solids from the water, helping to clean and treat the water before it is released into the environment.

Conclusion

Vertical leaf filters equipped with filter bags are essential in various industrial applications for their ability to handle large volumes of liquids while maintaining high filtration efficiency. By applying pressure, these filters enable faster filtration rates and the effective removal of solids, making them invaluable in industries such as chemicals, food processing, pharmaceuticals, and wastewater treatment. The choice of filter bags, the understanding of their working principles, and proper maintenance are critical to ensuring the filter’s performance and longevity.