Maintaining and replacing liquid bag filters is crucial for the optimal performance and longevity of your filtration system. This comprehensive guide covers everything you need to know about liquid bag filters, including their importance, how to replace them, the tools required, common mistakes to avoid, and essential maintenance tips.

Table of Contents

ToggleWhat is a Liquid Bag Filter and Its Significance?

A liquid bag filter is a filtration tool employed across multiple industries to extract particulate impurities from liquid substances. These filters are essential for maintaining the purity of liquids, protecting downstream equipment, and ensuring that products meet quality standards.

Liquid bag filters are frequently utilized in sectors like water purification, food and beverage production, pharmaceutical manufacturing, chemical processing, and petrochemical industries.

Importance of Liquid Bag Filters

Enhanced Product Quality: By removing contaminants and impurities, liquid bag filters ensure that the final products meet stringent quality standards. This is especially critical in fields like pharmaceuticals and food processing, where the cleanliness of products is paramount.

Equipment Protection: Filtration prevents particulate matter from entering and damaging downstream equipment, reducing maintenance costs and downtime.

Operational Efficiency: Clean liquids improve the efficiency of industrial processes, leading to better overall performance and cost savings.

Environmental Conservation: Efficient filtration helps minimize the emission of pollutants into the environment, supporting sustainability initiatives and decreasing the environmental impact of industrial operations.

How to Replace a Liquid Bag Filter

Replacing a liquid bag filter is a straightforward process if done correctly. Here’s a comprehensive manual to assist you in changing your filter effectively and securely.

Step-by-Step Guide to Replacing a Liquid Bag Filter

Shut Down the System: Shut down the system and make sure it’s depressurized to prevent any mishaps. Follow your facility’s safety procedures to lock out and tag out (LOTO) the equipment.

Depressurize the Housing: Open the vent valve to release any residual pressure in the filter housing. This step is crucial to prevent any sudden release of pressure when opening the housing.

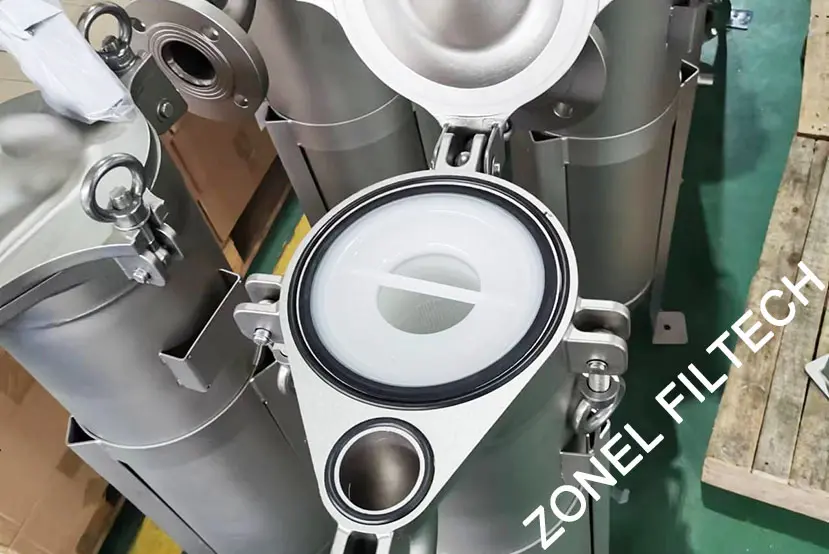

Open the Housing: Use the appropriate tool, such as a wrench or spanner, to unlock and remove the housing lid. Be cautious of any residual liquid that may spill out.

Remove the Used Filter Bag: Carefully lift out the used filter bag, avoiding spillage of contaminants. Dispose of the used bag according to your facility’s waste management protocols.

Inspect the Housing and Basket: Inspect the housing and support basket for wear, damage, or accumulation of residue. Clean the housing and basket if necessary.

Install the New Filter Bag: Place the new filter bag into the support basket, ensuring it fits snugly and is properly seated. Make sure the bag is aligned correctly to prevent leaks.

Close the Housing: Secure the housing lid, ensuring a tight seal to prevent leaks. Recheck all connections and seals.

Repressurize the System: Slowly open the inlet valve to allow liquid into the system and gradually repressurize the housing. Check for any leaks during this process.

Check for Leaks: Inspect the housing and connections for any leaks. If any are found, recheck the seals and ensure the housing is properly closed.

Choosing the Correct Replacement Parts for Your Liquid Bag Filter

Filter Bag Material: Choose a material compatible with the liquid and contaminants. Common materials include polyester, polypropylene, nylon, and PTFE. Each material has specific properties that make it suitable for different applications.

Micron Rating: Select a filter bag with the appropriate micron rating to effectively capture the specific contaminants in your process. Micron ratings can span from several microns to hundreds of microns.

Size and Fit: Ensure the replacement filter bag matches the dimensions of your filter housing for a proper fit. A correctly sized bag ensures efficient filtration and prevents leaks.

Tools Required to Replace Liquid Bag Filter

Wrench or Spanner: Necessary for opening and securing the filter housing.

Safety Gloves: Protects hands during the replacement process, especially when handling used filters and tools.

Safety Goggles: Shields eyes from potential splashes or debris.

Lockout-Tagout (LOTO) Devices: Ensures that the system remains shut down and secure during maintenance to prevent accidental startups.

Pressure Relief Tools: Such as a vent valve opener, used to safely depressurize the filter housing before opening it.

Catch Basin or Bucket: To gather any liquids that might leak out during the removal of the filter.

Cleaning Supplies: Includes brushes and cloths for cleaning the housing and support basket.

New Filter Bag: The replacement filter that will be installed.

Leak Detection Fluid: This helps in identifying any leaks after the new filter is installed and the system is repressurized.

Common Mistakes to Avoid During Liquid Bag Filter Replacement

Failing to Properly Shut Down the System: Not completely shutting down and locking out the system can lead to accidents and injuries. Always follow lockout-tagout (LOTO) procedures meticulously.

Not Fully Depressurizing the System: Starting the filter replacement without fully depressurizing the system can cause a sudden release of pressure, leading to spills or injuries.

Using Inappropriate Tools: Employing the wrong tools can damage the equipment or make the replacement process more difficult. Ensure you have the correct wrenches and tools for the job.

Neglecting Safety Gear: Skipping safety gloves, goggles, or other protective equipment can lead to personal injury from chemical exposure or physical harm.

Not Checking the Filter Housing and Support Basket: Skipping the inspection and cleaning of the filter housing and basket can lead to poor performance of the new filter, as residue or damage can impede its effectiveness.

Incorrect Installation of the New Filter: Misaligning the new filter or not ensuring a snug fit can cause leaks or reduce the efficiency of the filtration process.

Not Testing for Leaks After Installation: It’s crucial to check for leaks after reassembling the system. Leaks can lead to product loss and environmental hazards.

Maintenance Tips for Liquid Bag Filter

Regular Inspections: Periodically check the filter housing, support basket, and filter bags for signs of wear or damage.Identifying problems early can help avoid more significant issues later.

Monitor Pressure Differential: Watch the pressure difference across the filter. A significant increase in pressure indicates the filter bag is clogged and needs replacement.

Clean the Housing: During each filter bag replacement, clean the housing and support basket to remove any residue or contaminants. This helps maintain optimal filtration efficiency.

Lubricate Seals: Ensure seals and gaskets are properly lubricated to maintain a tight seal and prevent leaks. Regular lubrication extends the life of the seals.

Document Maintenance Activities: Maintain a record of all maintenance tasks, such as filter changes and checks, to monitor the efficiency and durability of the filter system. This record helps in scheduling timely maintenance and replacements.

Conclusion

Proper maintenance and timely replacement of liquid bag filters are crucial for maintaining the effectiveness and extending the life of your filtration system. By following the steps outlined in this guide and adopting best practices, you can maintain optimal filtration performance, reduce downtime, and extend the life of your equipment. Regular inspections, pressure monitoring, and using the right filter bags are key to achieving these goals. Proper maintenance and timely replacement not only improve operational efficiency but also contribute to a healthier and safer work environment.