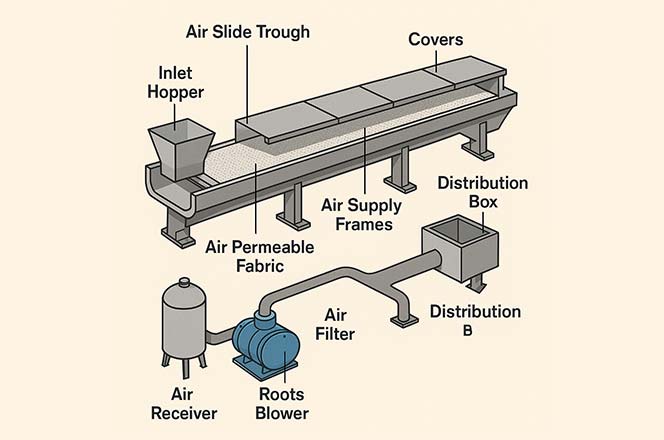

Air slide systems, or air gravity conveyors, play a key role in bulk material handling processes. These systems are designed to move fine, dry powders such as cement, fly ash, alumina, and flour efficiently and economically.

Unlike mechanical conveyors, air slide systems use a combination of low-pressure air and a fluidizing membrane to gently move materials along a sloped, enclosed trough.

Understanding the core components and their individual functions is essential for ensuring optimal operation, energy efficiency, and long-term reliability.

Table of Contents

ToggleAir Slide Trough

Structure and Material

The air slide trough is the main channel through which materials are transported. It is typically constructed of mild steel, stainless steel, or aluminum, depending on the application, material abrasiveness, and environmental requirements.

Function

The trough holds the bulk material and facilitates its controlled flow. It’s designed with a slight downward slope (usually 6°–12°) to enable gravity-assisted movement. The trough bottom holds air-permeable fabric, letting air fluidize the material above for smooth flow.

Air Permeable Fabric (Fluidizing Membrane)

Material and Design

One crucial and essential component. The air-permeable fabric (also called a fluidizing membrane) is typically made of polyester, aramid (Nomex), glass fiber, or cotton blends, selected based on temperature resistance, abrasion, and chemical compatibility.

Function

The membrane separates the air chamber below from the powder above. Low-pressure air enters the lower chamber and flows uniformly through the permeable fabric surface. The fine powder above becomes fluidized, reducing friction and enabling the powder to flow like a liquid under the force of gravity.

The uniformity, durability, and air permeability rate of this fabric directly impact system efficiency, wear, and maintenance intervals.

Air Supply System

This subsystem comprises several elements responsible for delivering air to fluidize the conveyed material.

Roots Blower or Centrifugal Fan

Function: Provides the low-pressure, high-volume air required for fluidization.

Specs: Typically operates at 0.05–0.15 bar. Selection depends on the air slide length, height, and material flow rate.

Air Receiver

Function: Maintains steady air pressure and flow by acting as reservoir.It also helps smooth out fluctuations from the blower.

Piping Network and Valves

Function: Directs air from the blower to each section of the air slide system. Includes control valves, pressure regulators, and check valves to modulate airflow based on operational needs.

Air Filters

Function: Prevents dust and impurities from entering the blower and downstream equipment. Clean air is essential for maintaining the integrity of the fluidizing fabric.

Inlet and Outlet Hoppers

Inlet Hopper

The inlet hopper is where the bulk material enters the air slide system from a silo, bin, or feed line. It may include:

- Flow control gates to regulate material feed

- Vibrators or fluidizing pads to prevent clogging

Outlet Hopper

Located at the discharge end, the outlet hopper collects the transported material and channels it into the next stage of processing, such as packaging, further conveying, or storage.

Air Slide Sections and Covers

Sections

Air slide systems are often constructed in modular sections, each fitted with an air chamber and fabric. These sections:

- Designed for fast, easy installation and simple maintenance, saving time and reducing effort.

- Can be customized for length, bend angles, and drop points

Covers

The top cover of the air slide:

- Prevents dust emission

- Protects the material from external contamination

- Often removable for inspection or maintenance

Some systems include inspection ports for visual checks and minor adjustments without full disassembly.

Distribution Box / Splitter / Diverter Valves

These are optional but essential when the system is used in a branched configuration.

Function

- Distribution boxes redirect material flow to multiple outlets.

- Diverter valves control which path the material takes.

- These components are typically pneumatically or electrically actuated for automated operation.

Proper design ensures balanced flow distribution, preventing blockages or overflows in multi-outlet systems.

Support Structure and Insulation

Support Frames

The entire air slide system must be supported by a steel frame, wall brackets, or hangars to maintain correct alignment and slope. The consistency of the slope is crucial to ensure smooth material flow.

Thermal Insulation (if applicable)

In some cases, the system conveys hot materials (e.g., hot cement clinker dust). Insulating materials like ceramic wool or glass fiber wraps are added to:

- Prevent heat loss

- Protect workers and surrounding equipment

- Extend the life of the fabric and steel housing

Instrumentation and Monitoring Systems

For automated plants or where system performance is critical, sensors and control devices may be integrated.

Common Components

- Pressure gauges: Monitor air pressure at various points.

- Airflow meters: Ensure optimal airflow through each section.

- Temperature sensors: Used especially when handling hot materials.

- Level sensors: Monitor material accumulation at inlet and outlet hoppers.

These instruments support predictive maintenance, optimize processes, and generate alarms during equipment failure, ensuring efficiency, safety, and reduced downtime.

Expansion Joints and Bends

Expansion Joints

Absorb thermal expansion in long air slide runs.

Prevent structural damage due to temperature-induced stress.

Bends and Elbows

Though air slide systems are generally linear, custom applications may include horizontal or vertical bends. These are engineered carefully to prevent:

- Material backflow

- Air turbulence

- Blockages

Smooth curvature and consistent fabric coverage in bends are essential for uniform flow.

Cleaning and Maintenance Features

Access Ports

- Located periodically along the system

- Enable internal cleaning or fabric inspection

Vibrators or Air Knocker Devices

- Attached externally to remove clinging material

- Help maintain smooth operation during extended use

Some systems also use manual or automatic purge air lines for periodic flushing of accumulated fines in the trough or outlet.

How These Components Work Together

In an operational air slide system, these components function in harmony:

- Material enters the system through the inlet hopper.

- The blower introduces low-pressure air through the lower chamber.

- Air flows through fabric, making powder fluid-like.

- Due to the sloped trough, the material flows slowly and steadily along the system.

- The material is discharged at the outlet hopper, and the air is either vented or recycled.

Each component contributes to energy savings, material flow accuracy, system longevity, and process cleanliness.

Advantages of Using an Air Slide System

Understanding the components also reveals the advantages of this technology:

- No moving parts in the conveying path → low maintenance and wear

- Dust-free operation thanks to enclosed design

- Low energy consumption due to low air pressure requirements

- Simple design with modular components for easy customization

Common Issues and Component-Related Troubleshooting

| Problem | Likely Cause | Affected Component | Solution |

| Uneven material flow | Worn or clogged fabric | Fluidizing membrane | Replace or clean fabric |

| Low discharge rate | Insufficient air pressure or volume | Blower or valves | Check blower output and valve settings |

| Material accumulation | Slope too shallow or fabric sagging | Trough or support system | Adjust slope or reinforce structure |

| System overheating | Lack of insulation | Insulation layer | Add or replace insulation |

| Dust leakage | Loose covers or broken seals | Air slide covers | Reseal or tighten cover bolts |

An air slide system is an elegant and efficient solution for conveying bulk powders in industrial applications. Its simplicity lies in its core components—the trough, fluidizing fabric, air supply, hoppers, and auxiliary control systems—all working in unison to create a smooth, energy-efficient flow of materials. Each component plays a specific, indispensable role: the trough provides the path, the air ensures fluidization, and the fabric is the magic layer that ties it all together.

Understanding these key components and their functions empowers plant operators, engineers, and procurement specialists to make informed decisions about design, maintenance, and system upgrades. As industries continue to push for greater efficiency, sustainability, and automation, air slide systems remain a cornerstone of modern dry bulk material handling.