While invisible, it can trigger devastating explosions, damage equipment, interrupt production, and put workers’ lives at risk. Industries handling combustible dust—such as chemicals, cement, grain, metalworking, and plastics—must fully understand the dangers and adopt effective preventive measures. One of the most reliable defenses is the use of anti-static needle felt filter cloth, engineered to safely dissipate static charge before it becomes a hazard.

Table of Contents

ToggleWhy Static Electricity Builds Up Inside Dust Collection Systems

Static electricity occurs when particles collide, rub, or separate from surfaces. A dust collection system offers the perfect environment for this:

Constant Particle Movement

Airborne dust particles flow at high speed through ducts, hoppers, and filter bags. The friction generates continuous electrostatic charge.

Dry, Insulating Dust Materials

Many industrial dusts—plastic, sugar, starch, cement, resins—are excellent insulators, meaning they hold onto static charge rather than releasing it.

Low Humidity Conditions

Plants running drying systems, high-temperature processes, or operating in winter conditions tend to have low humidity, further increasing static charge accumulation.

Non-Conductive Filter Cloth

Standard filter cloth materials (e.g., polyester, polypropylene, acrylic) easily store static charge because they are non-conductive.

Fast Airflow and Turbulence

Higher airflow velocity increases friction, which increases electrostatic buildup. Systems with frequent pulsing, reverse air cleaning, or cyclone separators generate even more charge.

Why Static Electricity Is Dangerous: Explosion and Ignition Risks

Static electricity poses two major dangers: sparks and explosions.

When a charged filter bag or dust-laden duct suddenly discharges electricity, the resulting spark can ignite combustible materials.

Dust Is Often Highly Combustible

Many industries handle dusts with a low minimum ignition energy (MIE)—sometimes as little as 10–30 millijoules, which is far less than a typical static spark (up to 3,000 mJ).

Combustible dust examples with low ignition thresholds include:

- Flour, sugar, cocoa

- Aluminum, magnesium

- Resins, plastics

- Wood dust

- Coal dust

- Pharmaceuticals

- Pigments and fine chemicals

Dust Suspended in Air Creates an Explosive Atmosphere

When fine dust accumulates inside a filter bag chamber or hopper, it creates a fuel-rich environment. If stirred into suspension—such as during pulse-jet cleaning—it becomes extremely explosive.

Static Sparks Can Trigger Catastrophic Chain Reactions

A single spark inside a dust collector can trigger:

- A primary explosion inside the filter housing

- A secondary explosion from dust accumulated in surrounding areas

- Fire inside the ductwork

- Damage to blowers, rotary valves, and silos

- Complete loss of equipment or facility

Metal Parts Cannot Prevent Static Sparks

Some assume grounding the metal housing is sufficient. It’s not.

Most static charge comes from the dust interacting with the filter cloth itself, not from the metal frame.

This is why the filter media must be anti-static.

Real-World Examples of Static-Induced Dust Explosions

2008 Georgia Sugar Refinery Explosion (USA)

Ignition of sugar dust led to 14 deaths, 36 injuries, and complete destruction of the plant. Static sparks were identified as one likely ignition source.

Aluminum Polishing Plant Explosion (China)

A static discharge in a dust extraction system caused a fireball, leading to 75 fatalities and over 180 injuries.

Flour Processing Plants (Global)

Multiple flour mills have experienced explosions traced to static build-up inside filter bags during pulse cleaning cycles.

These tragedies highlight the need for anti-static filtration materials in any combustible dust environment.

Understanding How Dust Explosions Occur (The Explosion Pentagon)

Dust explosions require five elements:

| Element | Description |

| Fuel | Combustible dust (powder, fiber, fines) |

| Oxygen | Air in the system |

| Dispersion | Dust suspended in the air |

| Confinement | Inside duct, hopper, or baghouse |

| Ignition Source | Static spark, flame, or heat |

Static electricity is one of the most common ignition sources, especially in high-velocity dust filtration and pneumatic conveying systems.

Where Static Electricity Is Most Dangerous in a Dust Collection System

Static buildup is common throughout the system, but most dangerous at:

Filter Bag Surfaces

Fine dust continuously rubs against the filter cloth, generating charge.

Pulse-Jet Cleaning Area

Dust becomes suspended in the air when pulse jets fire, creating a perfect explosive atmosphere.

Hopper and Dust Discharge Zones

Falling dust creates both friction and separation, accelerating charge accumulation.

Ductwork Bends and Transitions

Fast-moving dust rubbing against the duct surface generates high electrostatic charge.

High-Temperature Areas

Hot, dry air enhances static buildup, especially in cement kilns, asphalt plants, and foundries.

How Anti-Static Filter Cloth Works (And Why It Prevents Explosions)

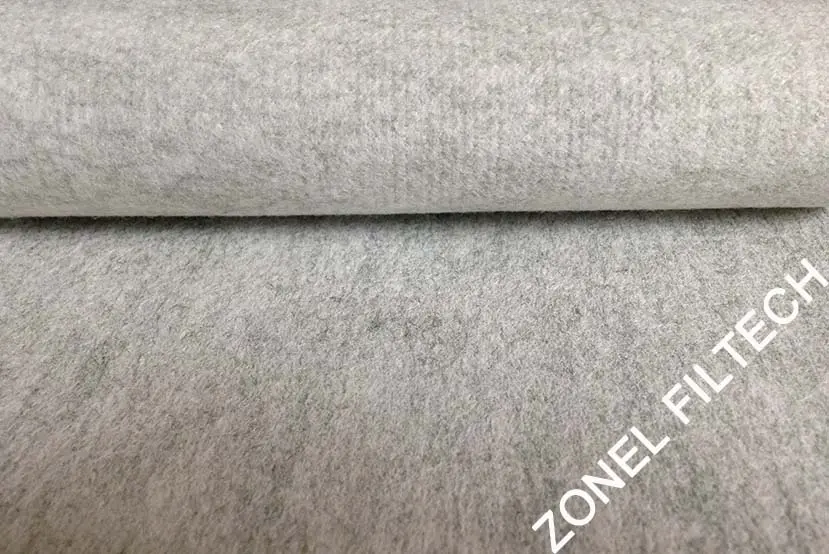

Anti-static needle felt filter cloth is specially engineered to dissipate static electricity safely, preventing spark generation. It does this through:

Conductive Fibers Woven Into the Felt

Stainless steel fibers, carbon fibers, or conductive yarns are incorporated into the felt structure at controlled spacing.

These fibers:

- Carry charge away from dust-laden areas

- Release the charge gradually and safely

- Prevent dangerous charge accumulation

Surface Electrically Conductive Treatment

Some anti-static felts receive special surface coatings that improve charge dissipation.

Reliable Grounding via Filter Cage

When combined with properly grounded filter cages, anti-static filter bags create a full static discharge pathway.

Preventing High Charge Density Hot Spots

Anti-static media evenly spreads out electrostatic buildup across the cloth surface, preventing sudden spark discharges.

Benefits of Using Anti-Static Filter Cloth

Using anti-static filter cloth in dust collection systems delivers both safety and performance improvements:

Prevents Static Sparks and Explosions

The main benefit: a safe, spark-free filtration system.

Improves Filtration Efficiency

Conductive fibers often help reduce dust adhesion.

Prevents Filter Blinding

Less dust adhesion = longer filter life + stable pressure drop.

Extends Service Life of Dust Collector

Reduces risk of thermal damage or fire.

Required for ATEX, OSHA, and NFPA Compliance

Industries in Europe and the U.S. often legally require anti-static media for combustible dust.

Safer for Workers and Equipment

Prevents catastrophic secondary explosions that often cause most injuries.

Industries That Must Use Anti-Static Filter Cloth

Industries dealing with combustible or fine dusts benefit the most:

- Flour mills and food processing

- Grain handling and storage

- Pharmaceutical and chemical production

- Plastics compounding and pelletizing

- Metal powder processing (aluminum, magnesium, titanium)

- Mining and cement plants

- Woodworking and MDF plants

- Textile and fiber processing

- Powder coatings manufacturing

- Tobacco processing

- Coal-fired boilers and power plants

In these environments, standard filter cloth can be extremely dangerous.

Comparison Table: Normal Filter Cloth vs Anti-Static Filter Cloth

| Feature | Standard Filter Cloth | Anti-Static Filter Cloth |

| Combustible Dust Safety | ❌ Unsafe | ✔ Prevents ignition |

| Static Charge Build-Up | High | Low |

| Static Discharge | Sparks likely | Safely dissipated |

| Conductive Components | No | Yes (conductive fibers/yarns) |

| Explosion Prevention | Limited | Excellent |

| Filter Life | Medium | Longer due to less blinding |

| Regulations Compliance | May fail NFPA/ATEX | Meets standards |

Types of Anti-Static Needle Felt Filter Cloth

Anti-static properties can be added to many common filtration materials:

Polyester (PET) Anti-Static Felt

Most common and cost-effective option.

Aramid (Nomex) Anti-Static Felt

Used in high-temperature dust filtration (≤ 204°C).

PPS (Ryton) Anti-Static Felt

Resistant to chemicals and performs well at high temperatures

Acrylic Anti-Static Felt

Common in low-temperature, corrosive environments.

PTFE Anti-Static Felt

Premium filtration with maximum chemical resistance.

How Anti-Static Filter Cloth Prevents Ignition

| Ignition Problem | How Anti-Static Filter Cloth Solves It |

| High static charge on filter surface | Conductive fibers dissipate charge |

| Sparks during pulse jet cleaning | Charge is grounded before a spark can form |

| Fine dust suspension creates explosive atmosphere | Anti-static cloth removes ignition source |

| Dust adhesion causing hot spots | Reduced resistance lowers heat buildup |

| Poor grounding of filter media | Integrated conductive yarn ensures charge flow |

Additional Safety Measures for Dust Collection Systems

Using anti-static filter cloth is essential, but should be paired with:

Explosion Vents or Panels

Relieve pressure during an explosion.

Spark Detection and Suppression Systems

Stops sparks before they reach the baghouse.

Proper Grounding of Equipment

Ductwork, cages, hoppers, and silos must be grounded.

Regular Housekeeping

Dust accumulations outside the baghouse can fuel secondary explosions.

Inert Gas Blanketing

Used in highly combustible environments.

Proper Humidity Control

Increasing humidity reduces static formation.

Compliance with NFPA 652, 654, 68, 69

Following dust hazard analysis (DHA) requirements.

Choosing the Right Anti-Static Filter Cloth

When selecting anti-static filter cloth, consider:

Dust Type

Is the dust:

- Conductive or insulating?

- Fine or coarse?

- Moisture-prone or dry?

- Abrasive or sticky?

Operating Conditions

Temperature, humidity, chemical exposure.

Air-to-Cloth Ratio (A/C)

Correct sizing ensures long filter life.

Conductive Fiber Type

Options include:

- Stainless steel fibers

- Carbon fibers

- Conductive yarn

Filtration Efficiency Requirements

Higher efficiency often needed in food, pharma, plastics.

ATEX or OSHA Certification Needs

Many facilities require certified anti-static solutions.

Static electricity is an invisible but deadly threat inside industrial dust collection systems. When ignited, combustible dust can unleash devastating explosions, endanger workers, and destroy entire facilities. Anti-static filter cloth plays a critical role in preventing this by safely dissipating electrical charge before it becomes a danger. By choosing the right anti-static needle felt and combining it with proper system design, grounding, and explosion protection, industries can operate safely, comply with global standards, and ensure long-term reliability.