Filter Presses

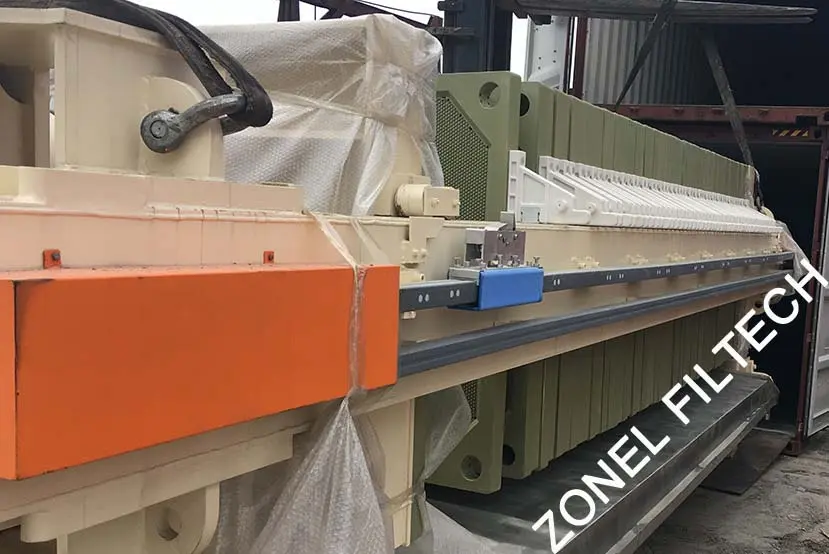

Besides the filter press fabrics and service, Zonel Filtech also can suggest and supply the filter presses according to clients’ solution content and processing circumstances so as to get the best filtration performance but the most economical investment, the filter presses can be frame plate filter press, chamber filter press and membrane filter press, which can be designed to total automatic so as to get the simplest way and shortest time to operate.

Especially the breakthrough in TPE diaphragm technology, filter presses from Zonel with the properties of endurable, stable, universalizable, and widely used in various industries.

Variable filter chamber technology is widely applied on solid-liquid separation in many industries such as chemical, pharmacy, mining, and so on which help to reduce the water content of the filter cake and extremely improved the production efficiency for our clients.

Filter Press

General introduction:

Filter press (sometimes called Plate-and-Frame Filter press) describes the style of filters developed from the 19th century onwards originally for clay. The majority of today’s filters are more correctly called “chamber filter press”, “Membrane filter press”, or “Membrane Plate Filter”. Many processes in the food, chemical, or pharmaceutical industries make products from liquid-solid suspensions or slurries. These mixtures are like a runny mud or milkshake. The solids in them do not dissolve in the liquid but are carried along in it. Filter presses separate the solids from the liquids so that the useful part can be processed, packaged, or delivered to the next step.

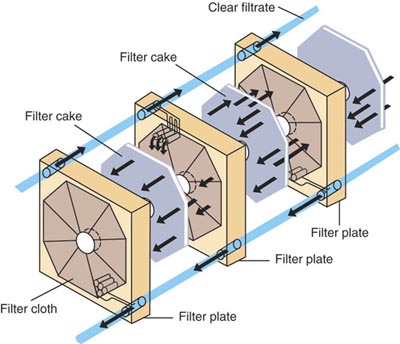

Filter presses generally work in a “batch” manner. The plates are clamped together, and then a pump starts feeding the slurry into the filter press to complete a filtering cycle and produce a batch of solid filtered material, called the filter cake. The stack of plates is opened, the solid is removed, the stack of plates is re-clamped and the filtering cycle is repeated.

A filter press uses increased pump pressure to maximize the rate of filtration and produce a final filter cake with a water content under 65%. This is more efficient than regular filtration because of the increased filtration pressure applied by the pump that can reach anywhere between 50-200 PSI. A filter press consists of a series of filter chambers formed between square, rectangular or round filter plates supported on a metal frame. Once the filter chambers are clamped, the filter press is loaded with slurry. The plates on the filter press are clamped together with hydraulic rams that generate pressures typically in the region of 3000 pounds per square inch.

In addition to the filter plate filtration medium, the growing filter cake enhances the removal of fine particles in the slurry. The solution coming through the filter press water bibs, called the filtrate, will be pure.The filtrate can be drained away for safe disposal, or it can be kept in a water tank for recycled use. At the end of filtration, the solid filter cake can be removed. The whole filtration process is often controlled by electronics to make it automatic or semi-automatic.

The typical parameters

Model

Filter area (㎡)

Plate size (mm)

Cake thick (mm)

Chamber Volume (dm³)

Plate No. (pcs)

Filter Pressure (MPa)

Motor Power (KW)

Weight (kg)

Dimension (LXWXH) mm

XXG30/870-UX

30

870*870

≤35

498

23

≥0.8

2.2

3046

3800*1250*1300

XXG50/870-UX

50

870*870

≤35

798

37

≥0.8

2.2

3593

4270*1250*1300

XXG80/870-UX

80

870*870

≤35

1280

61

≥0.8

2.2

5636

6350*1250*1300

XXG50/1000-UX

50

1000*1000

≤35

776

27

≥0.8

4.0

4352

4270*1500*1400

XXG80/1000-UX

80

1000*1000

≤35

1275

45

≥0.8

4.0

5719

5560*1500*1400

XXG120/1000-UX

120

1000*1000

≤35

1941

69

≥0.8

4.0

7466

7260*1500*1400

XXG80/1250-UX

80

1250*1250

≤40

1560

29

≥0.8

5.5

10900

4830*1800*1600

XXG160/1250-UX

160

1250*1250

≤40

3119

59

≥0.8

5.5

14470

7130*1800*1600

XXG250/1250-UX

250

1250*1250

≤40

4783

91

≥0.8

5.5

17020

9570*1800*1600

XXG200/1500-UX

200

1500*1500

≤40

3809

49

≥0.8

11.0

26120

7140*2200*1820

XXG400/1500-UX

400

1500*1500

≤40

7618

99

≥0.8

11.0

31500

11260*2200*1820

XXG500/1500-UX

500

1500*1500

≤40

9446

123

≥0.8

11.0

33380

13240*2200*1820

XXG600/2000-UX

600

2000*2000

≤40

11901

85

≥0.8

15.0

54164

13030*3000*2500

XXG800/2000-UX

800

2000*2000

≤40

14945

107

≥0.8

15.0

62460

15770*3000*2500

XXG1000/2000-UX

1000

2000*2000

≤40

19615

141

≥0.8

15.0

70780

18530*3000*2500

The accessories of filter presses

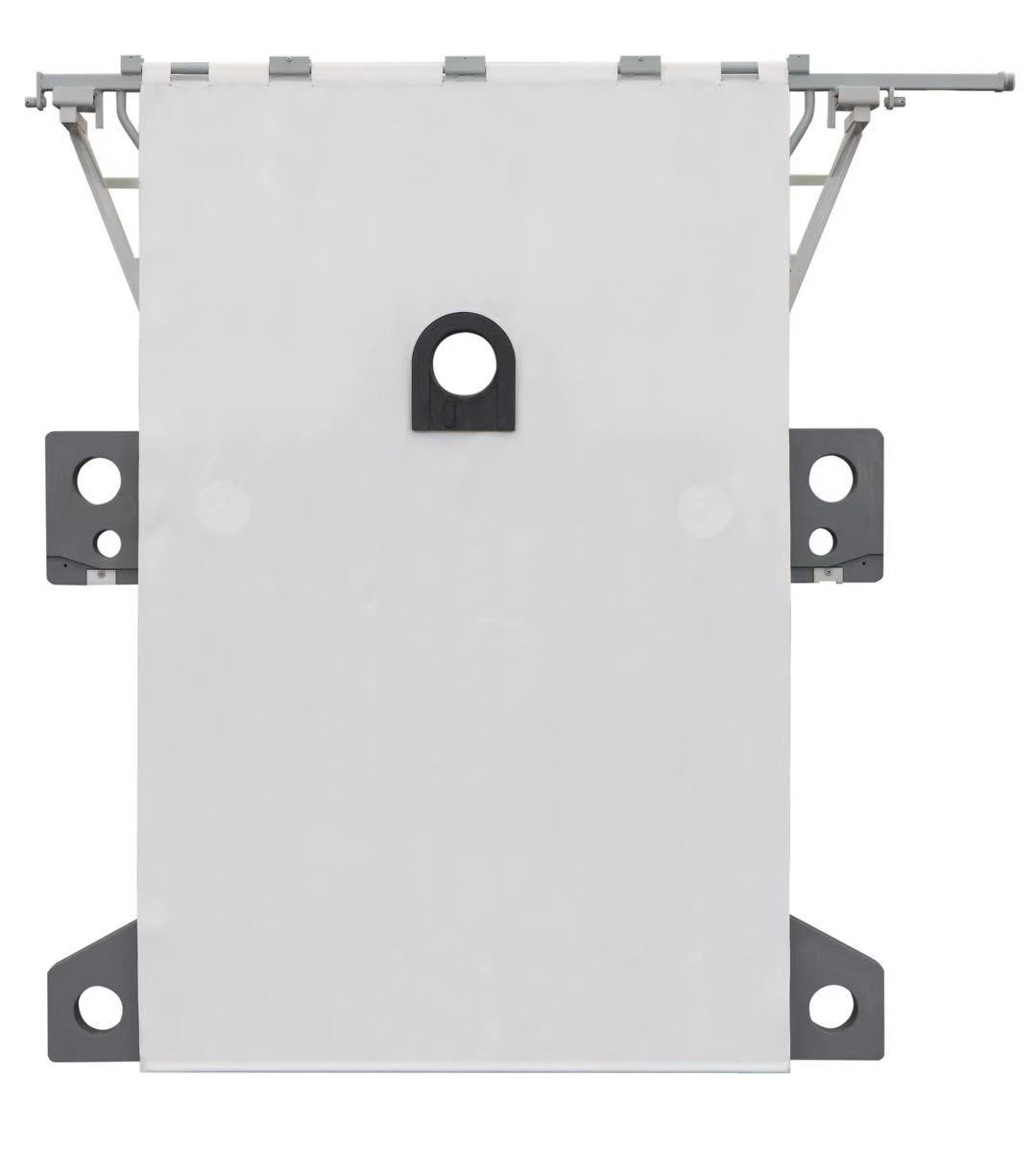

The accessories of the chamber filter press – Food grade filter press plates.

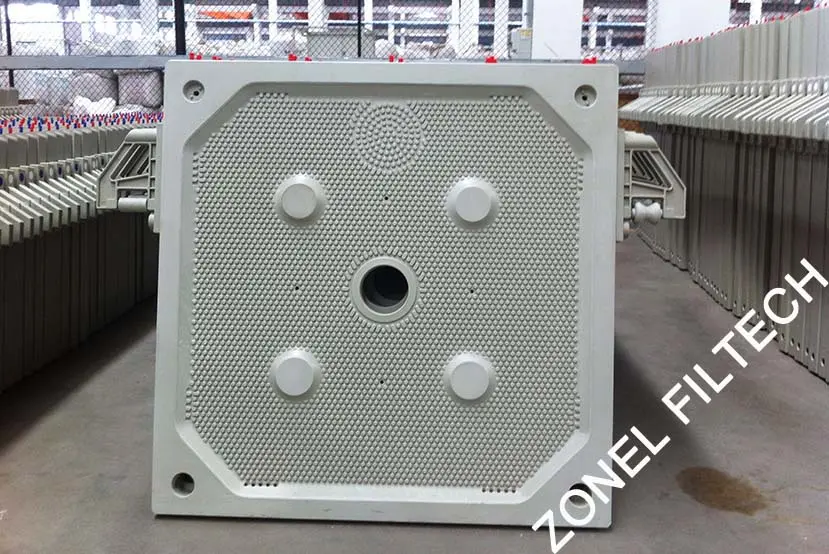

The accessories of the chamber filter press – filter plates.

The accessories of the chamber filter press – filter press plates.

Filter press plate.

The accessories of the chamber filter press – hydraulic station.

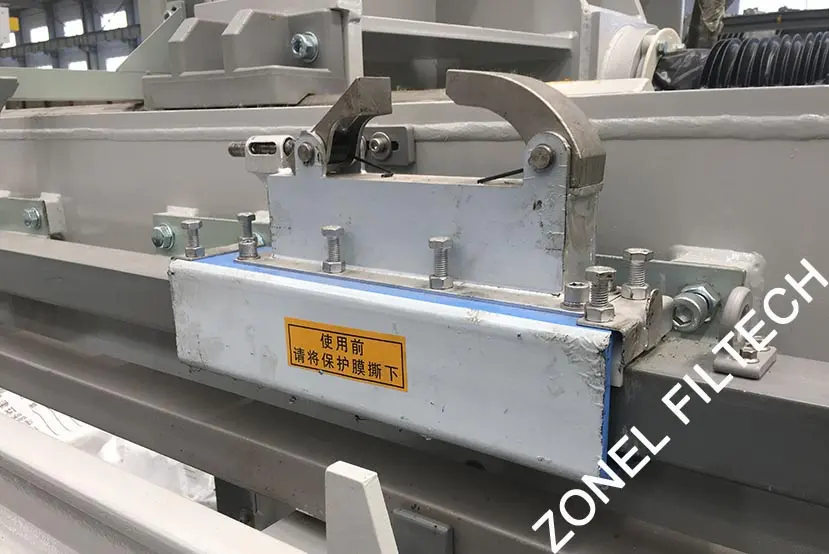

The accessories of the chamber filter press – Automatic plates pulling system.

The accessories of the chamber filter press – drainer chute.

The accessories of the chamber filter press – filter plate handle.