Filter Fabrics For Sugar Plants/ Sugar Industry Filter Cloth

Mostly the raw materials for sugar production will be sugar cane and sugar beet, according to the different clarify methods, which can be divided into carbonized sugar (lime+CO2) and sulfurized sugar (lime+SO2) sugar, though the carbonized sugar is more complex and needs much investment on the machines and Clariant, but the general processing principle and procedures are similar. And the filtering process will be requested for sugar slime concentrating after the clarification, sugar juice filtration (after CO2 insert), syrup purification, crystal dewatering processing (centrifuge filters), and wastewater processing, such as sugar cane and sugar beet washing water processing, filter fabric washing water processing, sediment dewatering processing, etc. The filter machine can be filter presses, vacuum belt filters, vacuum drum filters, centrifuge filters, etc. Zonel Filtech is the top expert who can offer full solutions for filter processing for sugar plants, any help needed, please feel free to contact us!

General introduction of the filter fabrics for sugar plants

Mostly the raw materials for sugar production will be sugar cane and sugar beet, according to the different clarify methods, which can be divided into carbonized sugar (lime+CO2) and sulfurized sugar (lime+SO2) sugar, though the carbonized sugar is more complex and needs much investment on the machines and Clariant, but the general processing principle and procedures are similar.

And the filtering process will be requested for sugar slime concentrating after the clarification, sugar juice filtration (after CO2 insert), syrup purification, crystal dewatering processing (centrifuge filters) and the wastewater processing, such as sugar cane and sugar beet washing water processing, filter fabric washing water processing, sediment dewatering processing, etc. The filter machine can be filter presses, vacuum belt filter, vacuum drum filter, centrifuge filters, etc.

Zonel Filtech is the top expert can offer fully solutions for the filter processing for sugar plants, any help needed, please feel free to contact us!

The technical specification of the filter fabrics for sugar plants

Series | Model number | Density (warp/weft) (counts/10cm) | Weight (g/sq.m) | Bursting strength (warp/weft) (N/50mm) | Air permeability (L/sqm.S) @200pa | Construction (T=twill; S=satin; P=plain) (O=others) |

Sugar plants Filter fabrics | ZF-PPDF64 | 630/214 | 326 | 3250/2350 | 110 | S |

ZF-PPD128 | 1134/440 | 310 | 4500/2200 | 90 | O | |

ZF-PPM116 | 291/130 | 475 | 5000/2300 | 80 | T | |

ZF-PPD2038 | 625/284 | 400 | 3500/1800 | 400 | O | |

ZF-PPDF623 | 301/200 | 1350 | WARP>21000 | 300 | O |

The properties of the filter fabrics for sugar plants

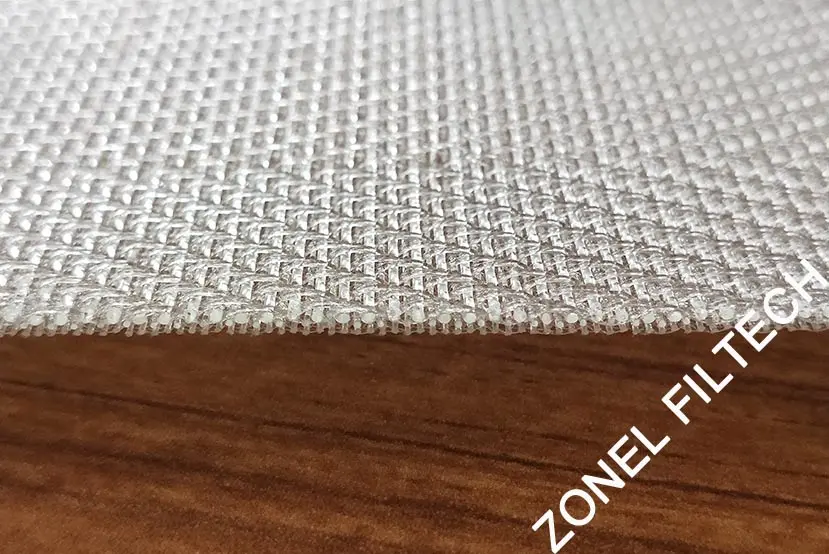

The filter fabrics from Zonel Filtech for sugar plants with the properties of:

1. high tensile strength and abrasion resistance, long service life.

2. smooth surface, easy cake release, with the perfect performance for sticky slurry dewatering.

3. acid and alkali resistance, food grade.

4. easy wash, seldom blocked/damped, good regeneration ability.

The detailed applications of the filter fabrics for sugar plants

The PP woven filter fabrics (monofilament blended with multifilament filter fabric, monofilament filter fabric, multifilament filter cloth)introduced above mainly used for filter presses, drum filters, volume belt filters, centrifuge filters in sugar plants for sugar slime concentrating after the clarification, sugar juice filtration (after CO2 insert), syrup purification, crystal dewatering processing (centrifuge filters) and the wastewater processing, such as and sugar cane and sugar beet washing water processing, filter fabric washing water processing, sediment dewatering processing, etc.