In industries that rely heavily on solid-liquid separation, filtration equipment plays a vital role in optimizing performance, reducing waste, and improving productivity. Zonel Filtech, a global filtration solution provider, not only offers a wide selection of filter press fabrics and after-sale services but also supplies complete filter press systems tailored to individual process conditions.

Table of Contents

ToggleUnderstanding Filter Presses

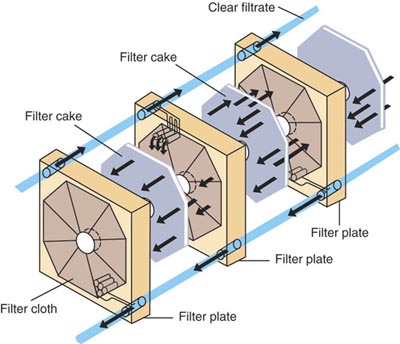

A filter press separates solids from liquids by pumping slurry into chambers with filter fabric, trapping solids as “filter cake” and allowing the filtered liquid, or filtrate, to exit.

Zonel Filtech designs and supplies frame plate, chamber, and membrane filter presses, offering optimal configurations based on the client’s operational goals, such as filtration speed, dryness of the filter cake, and maintenance efficiency.

Customized Filtration Solutions

Every filtration scenario is different. Factors like chemical content, temperature, particle size distribution, and desired moisture levels in the final product greatly impact the choice of filter press. Recognizing this, Zonel Filtech not only supplies equipment but also consults with clients to provide custom filtration solutions.

By considering the solution content (chemical properties of the slurry) and processing circumstances (pressure, temperature, batch volume, automation level), Zonel engineers recommend the most suitable filter press type and configuration. This results in optimized filtration performance with the lowest total cost of ownership.

Types of Filter Presses Provided by Zonel Filtech

Frame Plate Filter Press

The frame plate filter press is a classic design, particularly suitable for simple applications requiring low-pressure filtration. In this system, filter plates and frames alternate. The slurry enters the frame, solids are retained on the plate surface, and filtrate exits through the outlet ports.

Key features:

- Easy to clean and operate

- Suitable for coarse filtration or processes with low cake resistance

- Often used in industries like food, wastewater treatment, and metallurgy

Chamber Filter Press

The chamber filter press (also known as recessed plate press) is ideal for medium- to high-pressure applications. Each filter chamber is formed by recessed plates that are pressed together. The slurry fills the chambers, forming filter cakes without needing external frames.

Advantages:

- Higher dewatering efficiency than frame-plate models

- Fewer leak points due to gasket-sealed plates

- Better suited for medium- to high-solid concentration slurries

Zonel Filtech’s chamber filter presses can be designed with semi-automatic or fully automatic operation, depending on user needs.

Membrane Filter Press

The membrane filter press represents the most advanced configuration. It uses filter plates equipped with flexible membranes (usually made of TPE – Thermoplastic Elastomer) that can be inflated using air or water pressure to further squeeze the filter cake after initial filtration.

Benefits include:

- Significant reduction in cake moisture content

- Faster cycle time due to secondary pressing

- Enhanced cake washing capabilities

Membrane filter presses from Zonel are particularly effective in industries that require extremely dry filter cakes, such as pharmaceuticals, mining, and fine chemical processing.

Breakthrough in TPE Diaphragm Technology

One of Zonel Filtech’s most notable innovations is the advancement in TPE diaphragm technology used in their membrane filter presses. TPE (Thermoplastic Elastomer) offers an excellent combination of flexibility, chemical resistance, and mechanical strength, making it ideal for demanding filtration environments.

Key advantages of TPE diaphragms:

- Durability: Can withstand repeated inflation and deflation cycles, even under high pressure

- Chemical resistance: Suitable for aggressive chemical environments

- Flexibility and stability: Maintains shape and sealing even under temperature and pressure changes

- Universality: Compatible with a wide range of industries and slurries

These TPE diaphragms extend the life of the filter press and lower maintenance costs, while also enabling higher filtration efficiency.

Automation Options for Filter Press Systems

Zonel Filtech designs fully automatic filter presses, streamlining operations and reducing the need for manual intervention. Automation options include:

- Automatic plate shifting

- Hydraulic plate closing systems

- Automatic cloth washing systems

- Programmable logic controller (PLC) integration

- Filtrate and cake discharge automation

Fully automated filter presses are ideal for large-scale industrial applications where time, labor, and reliability are critical.

Variable Filter Chamber Technology

Zonel’s use of variable filter chamber technology further enhances process flexibility. These chambers can be adjusted in volume or configuration to match fluctuating production needs, product variations, or space limitations.

Applications of variable chamber systems include:

- Chemical industry: Efficient separation of fine suspensions and complex mixtures

- Pharmaceuticals: Precise control over separation and cake formation

- Mining and metallurgy: Handling slurries with abrasive solids

- Food and beverage: Removing impurities while preserving quality

This flexible design allows users to reduce downtime, adapt to changing demands, and maintain high throughput.

Industry Applications

Zonel Filtech’s filter press systems are used across a wide range of industries due to their reliability, customizability, and cost-effectiveness.

Chemical Industry

Used for separating chemicals from reaction byproducts or purifying intermediates. Membrane filter presses with TPE diaphragms ensure low moisture content, enhancing downstream processing.

Pharmaceutical Industry

The precision and hygiene required in pharma manufacturing make membrane filter presses the best option. Fully enclosed systems with automatic cleaning ensure contamination-free operation.

Mining and Metallurgy

For dewatering mineral slurries and tailings. Chamber presses and variable chamber systems improve water recovery and reduce tailings volume.

Food and Beverage

Used in sugar refining, juice clarification, and fermentation residue removal. Low-pressure frame plate systems ensure gentle processing.

Wastewater Treatment

Effective for municipal and industrial sludge dewatering. Filter presses reduce sludge volume, lowering disposal costs.

Economic and Operational Advantages

Choosing Zonel Filtech’s filter press solutions offers several benefits to operators and plant owners:

- Reduced Energy Consumption: Efficient diaphragm squeezing minimizes drying requirements.

- Lower Maintenance Costs: TPE diaphragms and automatic operations reduce wear and manual labor.

- Increased Throughput: Faster cycle times and high cake dryness improve overall production capacity.

- Longer Equipment Life: High-quality materials and precise engineering enhance reliability and uptime.

- Flexible Configurations: Frame, chamber, and membrane options adapt to any plant size or process type.

Environmental Benefits

In addition to economic performance, Zonel’s filter presses help companies meet environmental goals:

- Minimized Wastewater Volume: Enhanced dewatering reduces liquid discharge.

- Improved Recyclability: Cleaner filtrate and drier cakes can often be reused or more easily processed.

- Reduced Chemical Usage: Efficient filtration reduces the need for flocculants or coagulants.

With rising environmental standards worldwide, having a high-performance filtration system like Zonel’s helps industries stay compliant.

Why Choose Zonel Filtech?

Zonel Filtech combines engineering expertise with a deep understanding of filtration science. From recommending the right type of filter press to delivering turnkey solutions with automation and after-sales service, Zonel stands out through:

- Customized Design: Every system tailored to customer requirements

- Advanced Materials: TPE diaphragms and premium filter fabrics

- Global Experience: Trusted by clients in chemicals, mining, pharma, food, and more

- Integrated Service: Installation guidance, maintenance support, and spare parts supply

Whether your goal is higher efficiency, better moisture reduction, or labor-saving operation, Zonel Filtech delivers filter press systems that perform reliably over the long term.

Filter presses are a cornerstone of solid-liquid separation in modern industrial operations. With innovations like TPE diaphragm membranes, variable chamber technologies, and full automation, Zonel Filtech leads the way in offering high-efficiency, low-maintenance, and customizable filtration systems across industries.

By combining advanced technology with tailored engineering, Zonel Filtech helps businesses maximize output, reduce costs, and maintain environmental compliance—all with dependable performance.

For industries serious about filtration performance, investing in a Zonel Filtech filter press is more than a purchase—it’s a long-term productivity strategy.